Predictive maintenance in aviation has gotten complicated with all the vendor promises and marketing jargon flying around. As someone who worked alongside airline maintenance teams and watched this technology evolve from concept to daily operations, I learned everything there is to know about how these systems actually work. Today, I will share it all with you.

The short version? Airlines stopped waiting for things to break. They started replacing parts before failure. The numbers behind that shift are genuinely remarkable, and they’re the reason 100,000+ daily flights stay safe and mostly on time.

From Scheduled to Condition-Based Maintenance

The old way was brutally simple. Replace the brake assembly every 500 landings, whether it was worn or practically new. Swap the oil filter at 400 hours regardless of its actual condition. Safe? Absolutely. But wasteful to an almost absurd degree. Industry estimates peg 30-40% of scheduled component replacements as happening on parts that still had plenty of life left. I’ve personally seen brake assemblies pulled at interval that looked like they could have gone another 200 landings easy.

Modern aircraft generate the data to be smarter about all of this. A 787 Dreamliner kicks out roughly 500 gigabytes of operational data per flight. Engine sensors sample performance parameters 5,000 times every second. Structural sensors track fatigue loads across 60,000+ cycles daily. That continuous data stream is what makes condition-based maintenance possible — actual component health drives replacement decisions, not just a calendar or flight hour counter.

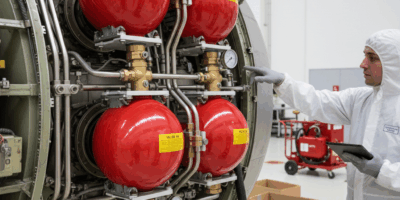

The Engine Analytics Revolution

Jet engines are where predictive maintenance really earns its keep, and it makes sense when you think about the costs involved. A single Rolls-Royce Trent XWB engine has over 25 sensors beaming real-time data to analytics centers on the ground. Temperature trends, vibration signatures, fuel flow deviations — all compared against databases spanning 50+ years of engine behavior data.

Probably should have led with this section, honestly. The results speak for themselves. Rolls-Royce’s TotalCare program cut unscheduled engine removals by 45% after implementing advanced analytics. That’s not a marginal improvement. GE Aviation’s digital twin technology — basically a virtual replica of every engine they have in service — predicts failures with better than 70% accuracy up to 30 days out. Pratt & Whitney’s EngineWise platform crunches 300+ data parameters per engine around the clock.

The Cost of Getting It Right

An in-flight engine shutdown is about as serious as it gets in commercial aviation. Beyond the obvious safety stakes, the financial hit is brutal. An aircraft-on-ground situation for a widebody runs $150,000 to $200,000 per day in lost revenue, crew repositioning, and passenger accommodation. The engine repair itself? Anywhere from $5 to $15 million when it’s unscheduled.

Predictive systems aim to shift that failure from an emergency to a planned event. An engine showing anomalies can finish its current trip, fly to a maintenance base under its own power, and get repaired during a scheduled overnight or weekly check. The same repair might cost 60% less when it’s done on your terms versus in crisis mode. I’ve seen airlines save millions on a single engine event just by catching it two weeks early.

Beyond Engines: Fleet-Wide Applications

This stuff now touches every aircraft system, not just the big-ticket engines. Landing gear health monitoring watches hydraulic pressure patterns to catch seal degradation. APUs transmit start cycle data that flags bearing wear. Even cabin systems get in on it — lavatory flush pressure sensors can predict pump failures before a single passenger notices anything off. That last one always gets a laugh when I mention it, but it’s real and it matters for passenger experience.

Airlines have built serious capabilities around this data. Delta TechOps has over 200 data scientists analyzing fleet health. United’s operations center fields 150,000+ system health messages every day, with AI sorting them into actionable maintenance items. American Airlines says predictive systems have slashed maintenance delays by 35% since 2019. That’s what makes predictive maintenance endearing to us data-driven aviation folks — it turns noise into decisions that actually help people.

The Machine Learning Frontier

Current systems are strong at matching patterns against known failure modes. That’s the baseline. The next generation goes further, using machine learning to spot failure signatures nobody has cataloged yet. Train algorithms on millions of examples of normal operations, and they get very good at flagging when something looks off — even if no human analyst would have caught it.

Airbus’s Skywise platform aggregates data from over 9,000 aircraft operated by 100+ airlines. That’s an unprecedented dataset. When a previously unknown correlation between ambient temperature and hydraulic valve performance popped up, affected components got replaced across the global fleet during routine checks — not during emergency groundings. That kind of catch is only possible at scale.

The Human Element

I want to be clear about something. Predictive maintenance doesn’t replace mechanics. It makes them better at their jobs. Technicians now show up at an aircraft already knowing which components need attention, with parts waiting and procedures ready to go. What used to require hours of exploratory troubleshooting becomes targeted, efficient repair. Maintenance hours per flight hour have dropped 23% over the past decade while dispatch reliability has climbed above 99.5% for modern fleets.

The machines that see failures coming represent aviation’s quiet revolution. Passengers almost never know when an alert prevented their delay or when a proactive swap avoided a diversion. They just experience a flight that left and arrived on time, completely unaware of the data streams making it all happen behind the scenes.