Honeycomb Panels in Aerospace Design

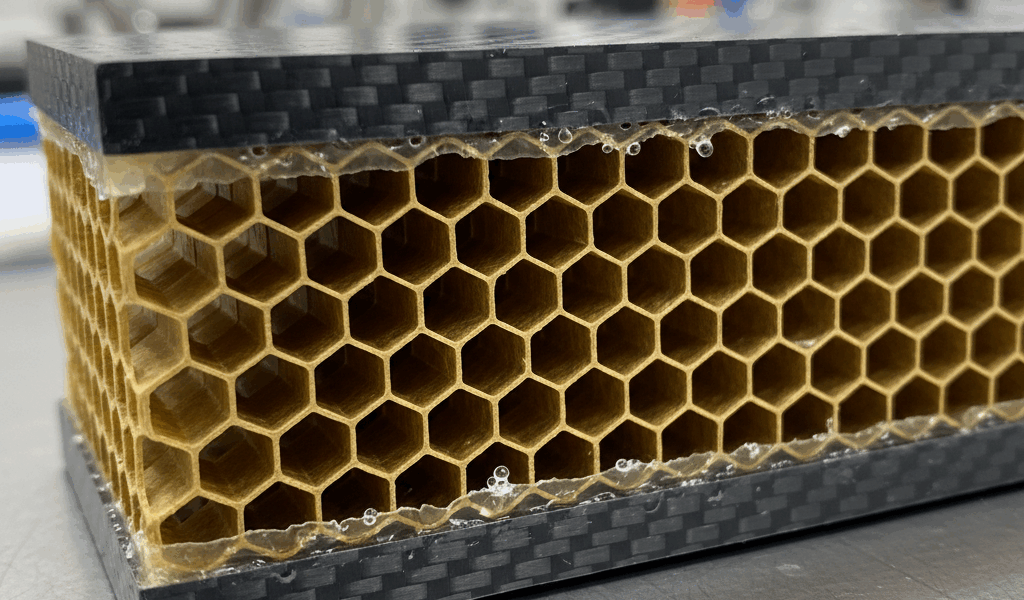

Honeycomb panels represent one of aerospace engineering’s most elegant solutions to a fundamental challenge: creating structures that are both incredibly strong and remarkably light. From commercial airliners to spacecraft, these hexagonal-celled structures have transformed how aircraft are built.

Why Honeycomb Works

The honeycomb structure achieves its strength through geometry:

- Load distribution: Hexagonal cells spread stress across the entire structure.

- Compression resistance: Cell walls resist crushing forces efficiently.

- Shear strength: The core maintains rigidity under lateral loads.

- Weight savings: Up to 90% lighter than solid panels of equal strength.

Aerospace Applications

Modern aircraft use honeycomb panels extensively:

- Flooring: Cabin floors supporting passenger loads with minimal weight.

- Control surfaces: Ailerons, elevators, and rudders requiring stiffness.

- Interior panels: Galleys, lavatories, and sidewall structures.

- Nacelle components: Engine cowlings and thrust reversers.

- Helicopter blades: Rotor blade cores providing torsional rigidity.

Material Choices

Aerospace honeycomb cores come in several materials. Aluminum honeycomb offers excellent strength-to-weight ratios for metallic structures. Nomex (aramid fiber) honeycomb resists fire and provides good fatigue resistance. Fiberglass honeycomb serves in radome applications where radar transparency matters. Titanium cores handle high-temperature environments near engines.

Manufacturing Process

Creating honeycomb panels involves bonding face sheets to the core. Manufacturers expand aluminum foil into hexagonal patterns or corrugate materials into cells. Adhesive films bond carbon fiber or aluminum skins to the core under heat and pressure. Precision tooling ensures consistent cell geometry and proper skin adhesion.

Inspection Challenges

Honeycomb structures require specialized inspection techniques. Ultrasonic testing detects skin-to-core disbonds. Tap testing remains a quick field method for finding damage. X-ray inspection reveals core crushing or moisture intrusion. Maintaining structural integrity requires regular inspection during aircraft service.

Future Developments

Advanced honeycomb designs continue evolving. Auxetic cores with negative Poisson’s ratio absorb impact energy better. 3D-printed honeycomb allows complex geometries impossible with traditional manufacturing. Thermoplastic honeycomb enables recyclable structures aligned with sustainability goals. These innovations ensure honeycomb remains central to aerospace design.